PCB testing

What is PCBA Testing?

PCBA testing involves the assessment of electrical continuity and the verification of input and output values of PCBA. PCB board designs incorporate specific numerical relationships between different test points, such as voltage and current. To validate whether the PCB board adheres to the design specifications, it is crucial to employ specialized test equipment for point-to-point testing. PCBA testing plays a pivotal role in guaranteeing the quality of production and timely delivery.

The Functional Circuit Test (FCT) fixture is custom-made based on the customer’s designated test points, procedures, and test steps. It serves as a platform where the PCBA board is securely positioned during the testing process, ensuring accurate and reliable test results.

PCBA Test Principle

The PCBA test principle involves connecting the test points on the PCBA board using FCT testing jigs to establish a complete path that links the computer and burner for uploading the MCU program. The MCU program captures user input actions, such as long-pressing a switch for a specified duration, and controls circuit operations, such as LED flashing or motor rotation, through calculations. The test of the entire PCBA board is completed by observing the voltage and current values between the test points on the FCT test jigs. This allows for the verification of whether these input and output actions align with the design requirements.

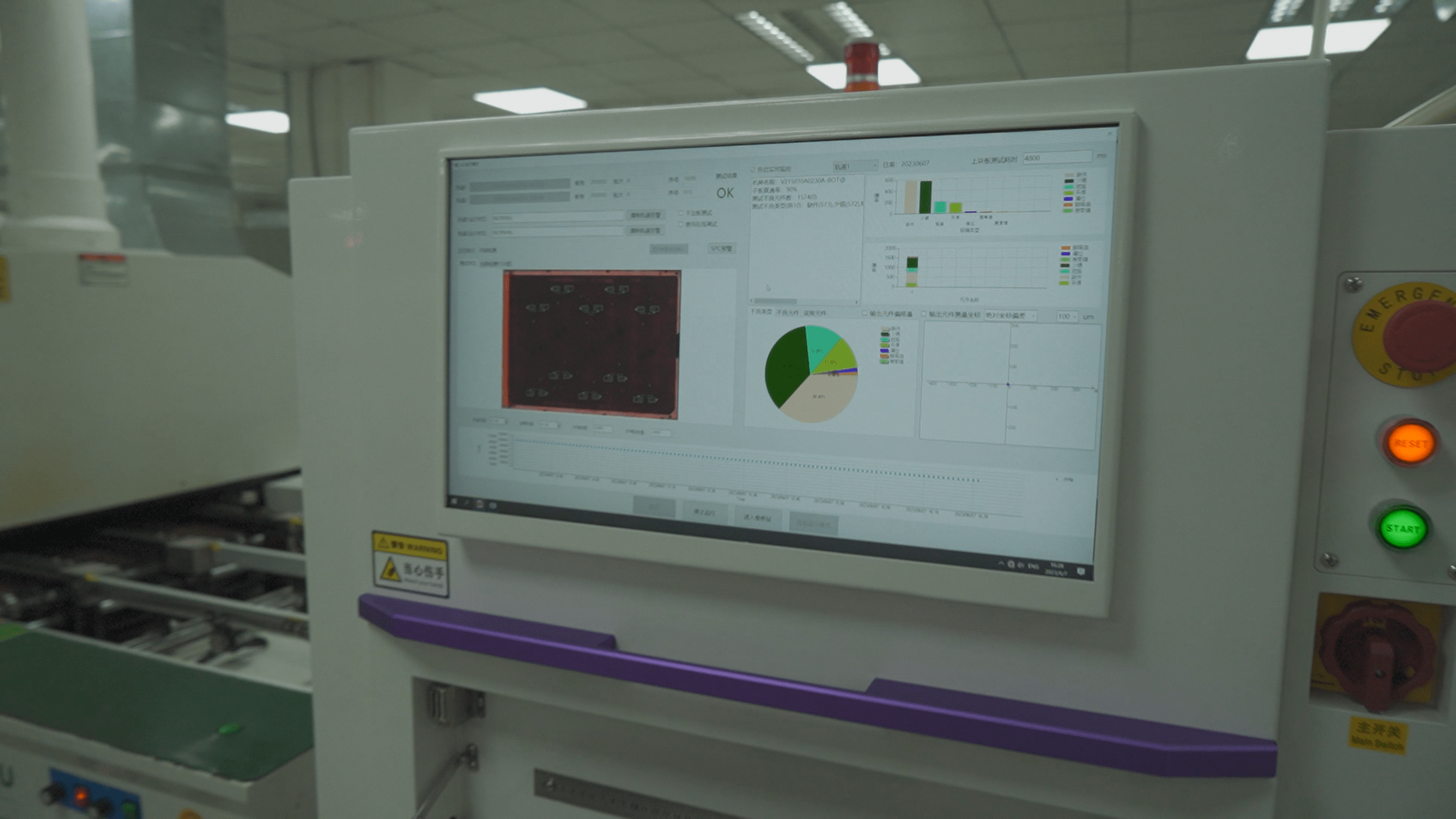

PCBA Test Jigs

To enhance productivity in testing large quantities of PCBA boards, the use of test jigs is essential. When the power is turned on, the test jig acquires key data, such as voltage and current, from the circuit and displays it on its screen, enabling rapid detection. During the PCB board design process, engineers consider the test plan and allocate PCB test points accordingly. They then issue a professional test document or test plan to the manufacturer.

PCBA testing is an indispensable and critical part of the entire PCBA manufacturing supply chain. It ensures quality control based on the final data results. In standardized design and manufacturing management practices, PCBA testing is highly recommended, carefully considered, and effectively implemented.

[wpforms id=”17″ title=”false” description=”false”]